WhatsApp:+86 16696206781

BAI-OTT Conveyor Belt Accessories Suppliers - 26 years of r&d of new splicing materials and rubber maintenance materials.

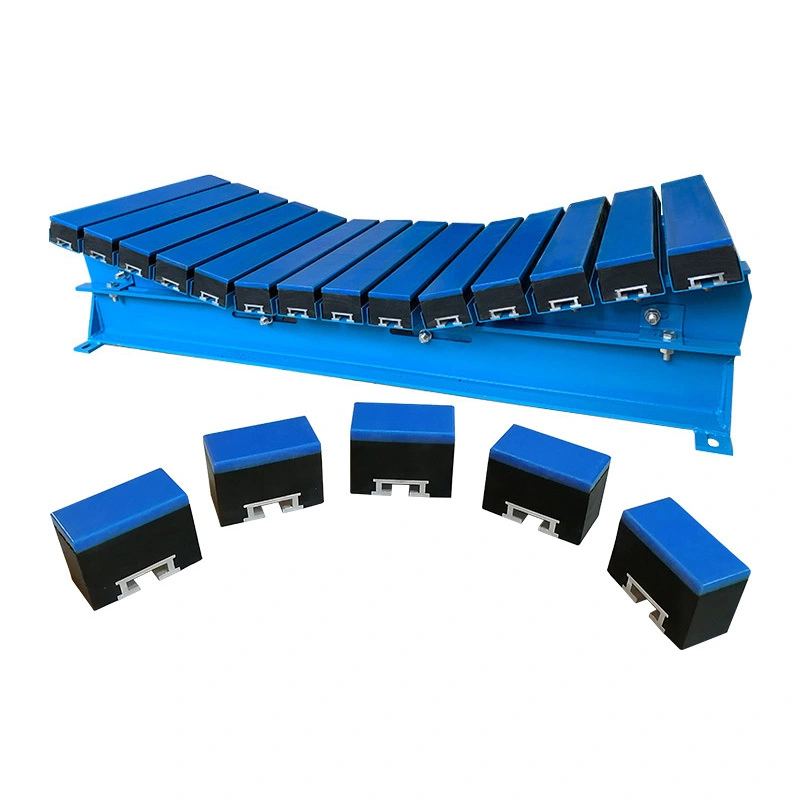

Adjustable Conveyor Impact Slider Bed

Impact bed is used in the loading area of conveyor belt to replace the traditional cushion rollers. It is designed to absord impact which will dramatically decrease impact from the falling materials to reduce the damage to the structure.

BAI-OTT provides ZJ-HCC impact beds for coal mine conveyor equipment, the steel fixed frame has excellent cushioning and corrosion resistance in coal mine high sulphur environment.

Product Introduction

Loading Zone Impact Bed has the characteristics of adjustable,high wear-resistant,high elastic,retardant which used in the loading area of the belt conveyor to replace the traditional cushion rollers.

It is designed to absorb impact loading which will dramatically reduce shock and stress loading to the structure.

Shape of impact bar

Note: The single slope is directional and runs in the opposite direction to the conveyor belt, while a double slope is not directional.

Advantage

● Conveyor impact buffer bar can effectively prevent the occurrence of uneven force on the conveyor belt and reduce the impact damage of the material;

● The surface material is smooth and wear-resistant UHMW-PE, which can reduce frictional resistance and prolong life;

● The middle layer of high elastic rubber of the impact bar can effectively absorb the impact of the material on the conveyor belt;

● The bottom layer uses special high-strength steel parts, which is light and does not rust, easy to install, and the impact bar can be replaced by a single piece;

● Conveyor impact buffer bar can be disassembled and assembled according to different carrying capacity, bandwidth and slot angle to improve production efficiency.

Specific specifications

At present, our company's existing impact bars molds can process lengths of 1220mm, 1400mm, 1500mm,1524mm etc., and the width is between 100-300mm. Our daily output is about 150-200 pcs, which can basically meet the requirements of our customers.

When materials strongly drop impact bed, rubber part mainly plays a good buffering role by the physical elasticity. Therefore, the rubber elasticity must up to certain level.

As international requirements, the rubber part of impact strip should be about Shore A 55° ( Mining usage must be treated flame retardant rubber), if the hardness is too high, it will be easy to break.

Besides, tear resistance, tensile strength, elongation at break, adhesion strength of rubber and metal profiles are also influence the service life of the products.

Elastic rubber is generally divided into three thicknesses of 50mm, 75mm and 100mm, and the width is 100mm. The choice of thickness is mainly determined by factors such as the impact force or the diameter of the drop materials during the operation.

The hot vulcanization is generally formed in a hot vulcanizing machine in one time. Heat the UHWMPE plate with the elastic rubber in a high temperature environment to make the surface molecules active.

And then bond the wear abrasive plate and the elastic rubber effectively prevent tackless during operation and increase service life.

Quality Certifications

● Cover Rubber

● Belt Noodle Gum

Detailed Parameter

|

UHMWPE |

Part |

|

|

Color |

Red or Custon |

|

|

Tensile breaking strength |

Mpa |

42 |

|

Elongation at break |

% |

400 |

|

Hardness |

Shore A |

61 |

|

Density |

G/CM³ |

0.93-0.94 |

|

Volume Abrasion |

CM³ |

0.00025 |

|

Molecular Weight |

Dalton |

500-900 |

|

High Elastic Rubber Part |

||

|

Color |

Black |

|

|

Strength of Extension |

Mpa |

17 |

|

Elongation at break |

% |

400 |

|

Hardness |

Shore A |

≤55 |

|

Rubber Impact elasticity |

% |

38 |

|

Bonding of metal n rubber |

N/mm |

12 |

|

Bonding of PE n rubber |

N/mm |

15 |

|

Fire Retardant Performance Index |

||

|

Volume Resistivity |

Ohm*m |

1E12 |

|

Surface Resistivity |

Ohm |

1E12 |

|

Dielectric Intensity |

KV/mm |

45 |

| Antistatic Performance Index | ||

| Relative Permittivity(100HZ) | —— | 2.1 |

| Dissipation Factor | E-4 | 3.9 |

| Dielectric Intensity | Ohm*m | >1E12 |

|

Recommended number of impact bars |

|||||||||||

|

Belt Width(mm) |

550 |

650 |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

|

Number of bars |

4 |

6 |

7 |

10 |

10 |

13 |

15 |

16 |

18 |

19 |

21 |

|

Further dimensions on demand. |

|||||||||||

Product Details

Product Parameters

| Material | PE+Rubber+Steel Bolt | Underground Applications | YES |

| Model | ZJ-HCC | Product Inspection | Available |

| Colour | Customised production | Lead Time | Ready to ship in stock |

| Belt Width | 650mm-2400mm | MOQ | 10 pcs |

| Belt Speed | Up to 1800 fpm (9m/s) | Warranty | 6 Months |

| Hardness | 60-70 Shore A | Supply Capacity | 4500 pcs/month |

| Sample | Available | Certification | ISO9001;ISO14001;ISO45001;CE;UPEM |

| Application | Coal mines, Cement plants, Steel plants, Power plants and other factories | Packing | Pallet, wooden case |

| Fracture | High elastic+Adjustable+High Wear-Resistant+High Quality | Delivery Time | 10~30pcs,1-3days/50~100pcs,3-5days |

| Corrosive Conditions | YES |

Product Specifications

More customised sizes on request

| Order NO. | Belt width/mm | Impact bar/mm | A/mm | B/mm | C/mm | L2/mm | Imapact bar | Weight/kg | ||||

| ZJ-HCC-650 | 650 | 1220 | 890 | 950 | 185 | 240 | 2 | 2 | 2 | 9 | 11 | 16 |

| ZJ-HCC-800 | 800 | 1220 | 1090 | 1150 | 188 | 270 | 2 | 2 | 2 | |||

| ZJ-HCC-1000 | 1000 | 1220 | 1290 | 1350 | 216 | 370 | 3 | 3 | 3 | |||

| ZJ-HCC-1200 | 1200 | 1220 | 1540 | 1600 | 246 | 420 | 3 | 3 | 3 | |||

| ZJ-HCC-1400 | 1400 | 1400 | 1750 | 1810 | 251 | 500 | 4 | 4 | 4 | 10.5 | 12.5 | 18.5 |

| ZJ-HCC-1600 | 1600 | 1400 | 1990 | 2050 | 296 | 580 | 4 | 4 | 4 | |||

| ZJ-HCC-1800 | 1800 | 1524 | 2210 | 2280 | 315 | 710 | 5 | 5 | 5 | 11.5 | 14 | 20 |

| ZJ-HCC-2000 | 2000 | 1524 | 2420 | 2500 | 342 | 2500 | 5 | 5 | 5 | |||

| ZJ-HCC-2200 | 2200 | 1650 | 2630 | 2710 | 367 | 900 | 6 | 6 | 6 | 12.5 | 15.5 | 22 |

| ZJ-HCC-2400 | 2400 | 1650 | 2840 | 2910 | 386 | 920 | 6 | 6 | 6 | |||

FAQs