WhatsApp:+86 16696206781

BAI-OTT Conveyor Belt Accessories Suppliers - 26 years of r&d of new splicing materials and rubber maintenance materials.

Solving the problem of silo wear-out - special ceramic wear-resistant lining solution

Silo wear is a major cause of production disruptions, increased maintenance costs, and safety hazards. Traditional metal liners often struggle with highly abrasive materials, and frequent repairs and replacements significantly impact operational efficiency. Our specialized ceramic wear-resistant lining solution is designed to completely address this persistent problem. It's more than a simple material replacement; it's a comprehensive approach based on deep industry expertise.

This solution utilizes high-purity alumina ceramic with a purity of 92% or higher, sintered at temperatures exceeding 1500°C. Its Rockwell hardness reaches HRA85 and above, offering wear resistance over 266 times that of manganese steel and 171.5 times that of high-chromium cast iron. We offer a variety of construction options to perfectly suit your specific operating conditions:

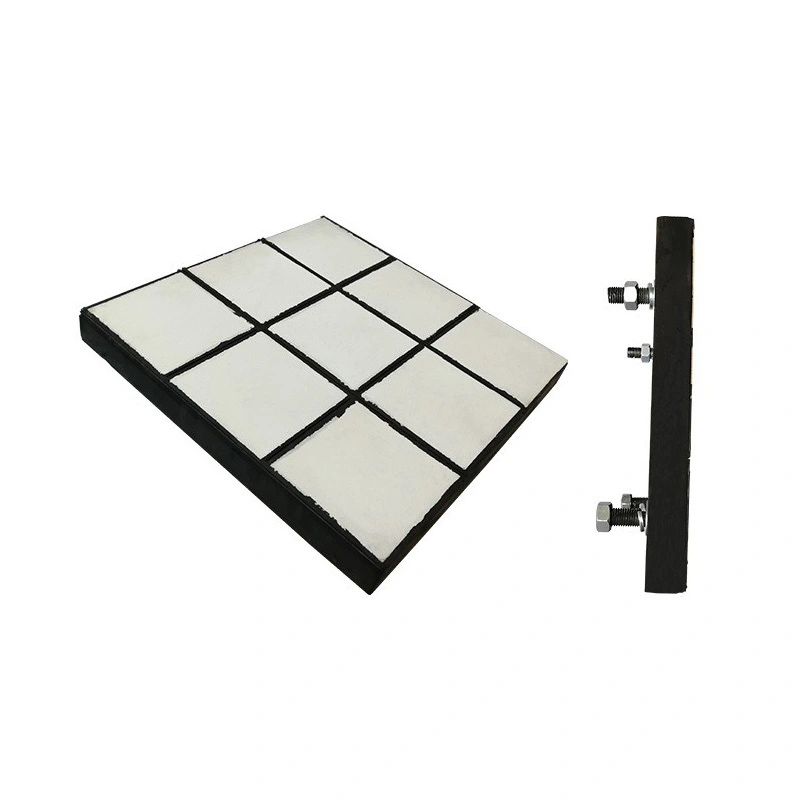

Structures of Ceramic Rubber Liner

● Alumina Ceramic: 92% & 95% Ceramic, available with extensive sizes and shapes

● Rubber/ PU Layer: Superior compound rubber/ polyurethane, impact-absorbing

● Connection: Steel plate & studs, CN bonding layer, ect

● Excellent bonding: Ceramic, rubber and steel plate are permanently bonded through our special molding and hot vulcanization process. Ceramics will stay in place until completely worn.

Feature Of Ceramic Liner

● High wear resistant rubber ceramic wear liner is embedding high alumina ceramic into energy absorbing rubber or polyurethane cushion, and bond both to steel backing plate via hot vulcanizing for easy installation.

● Impact absorbing rubber cushions helps reduce impact energy and prevent ceramic tiles breakage.

● CN bonding adhesive backed or Steel backing plate with studs for easy installation.

Advantage

● Hardness: the hardness of the material reflects the ability of the material to resist the material pressing into the surface. The higher the hardness, the shallower the depth of material intrusion, the smaller the volume of wear and the higher the wear resistance. The alumina content of wear-resistant ceramics exceeds 92% and the hardness reaches hra85 or above, which is the basis of wear resistance of wear-resistant ceramic tubes.

● Strength: high strength, which can provide good support for wear resistance and give full play to the ability of anti-wear and hard wear resistance, that is, strength and hardness complement each other. The bending strength of wear-resistant ceramics is 300-450 Mpa and the compressive strength is 1200-2500 Mpa, which further strengthens the wear resistance of wear-resistant ceramic pipes.

● Roughness: the smaller the roughness value, the higher the fatigue wear resistance. Under certain circumstances, the ceramic surface roughness is related to the thickness of powder particles. Wear resistant ceramics have been polished for many times, and are supported by high-quality fine powder. The smoothness is very high, which adds a third guarantee to the wear resistance of wear-resistant ceramic tubes.

The rubber and ceramic composite wear-resistant products is a customized product, it can be made in various shapes, selected composite material according liner wear of various thicknesses, forming a strong wear layer.

The unique toughening formula forms a strong crystal bond, which greatly enhances the impact resistance of alumina ceramics, which is 3 to 5 times that of general standard wear-resistant ceramics.

Different shapes and sizes

● Mosaic: 10x10x2~10mm, 17.5x17.5x2~15mm,20x20x2~15mm,33x33x7~25mm, etc.

● Square: 100x100x6~50mm, 150x100X6~50mm, etc.

● Hexagonal: S12xT3~20mm, S19xT6~25mm

● Spherical tiles: 40x40x40mm, 32x32x22mm, 38x38x38mm, etc.

● Cylinder/rod: 6x6mm, 15x15mm, 20x20mm, 31x31mm, 40x40mm, 50x50mm, etc.

Technical Data

Rubber Wear Resistant Ceramic Liner For Conveyor Hopper Bin Technical Data.

|

Ceramic Tile Specifications |

|

|

AL2O3(%) |

95±0.5 |

|

Bending Strength(Mpa) |

>280 |

|

Fracture Toughness(MPam1/2) |

>3.9 |

|

Rockwell Hardness(HRA) |

>88 |

|

Wear Volume(cm³) |

<0.3 |

|

Density(g/cm³) |

>3.7 |

|

Items |

Data |

|

Tensile Strength(Mpa) |

≥14 |

|

Break Extension(%) |

≥350 |

|

Shore Hardness(degree) |

55-65 |

|

Break Permanent Deformation(%) |

≤24 |

|

Rubber and Ceramic Adhesion Force(Mpa) |

≥3.0 |

|

Temperature Resistance(°C) |

≤100 |

Product Details

Product Parameters

| Main Ingredient | Ceramic/Rubber/Steel Plate | Lead Time | Ready to ship in stock |

| Model | ZJCER-OS | MOQ | 20sqm |

| Colour | Black | Warranty | 24 Months |

| Compressive Strength | 1200-2500Mpa | Supply Capacity | 8000sqm / month |

| Liner Shape | Customised sizes and shapes to suit site chute or silo conditions. | Certification | ISO9001;ISO14001;ISO45001;CE;UPEM |

| Product Construction | Steel plate + rubber + ceramic; rubber + ceramic; steel plate + ceramic | Packing | Pallet, wooden case |

| Sample | Provide | Delivery Time | 50~100sqm,3-5days/200~500sqm,7-10days |

| Product Inspection | Available |

Product Specifications

|

Order No. |

Product Name |

Dimension(mm) |

Ceramic Size(mm) |

Rubber Thickness(mm) |

Plate Thickness(mm) |

|

ZJCER-OS |

Hexagonal Ceramic Liner |

400*400 |

100*100*10 |

15 |

5 |

|

ZJCER-OS |

Hexagonal Ceramic Liner |

800*400 |

100*100*15 |

20 |

8 |

|

ZJCER-OS |

Hexagonal Ceramic Liner |

800*500 |

150*100*20 |

25 |

10 |

FAQs